California sports car manufacturer Czinger is hitting the road to success, with the highly anticipated delivery of its groundbreaking 21C hybrid supercar to customers set to commence later this year. Czinger has also made significant strides in forging partnerships with prominent players in the automotive and aerospace industries, driven by its innovative manufacturing techniques. The company is poised for substantial expansion in the coming decade, aiming to bolster its manufacturing capabilities.

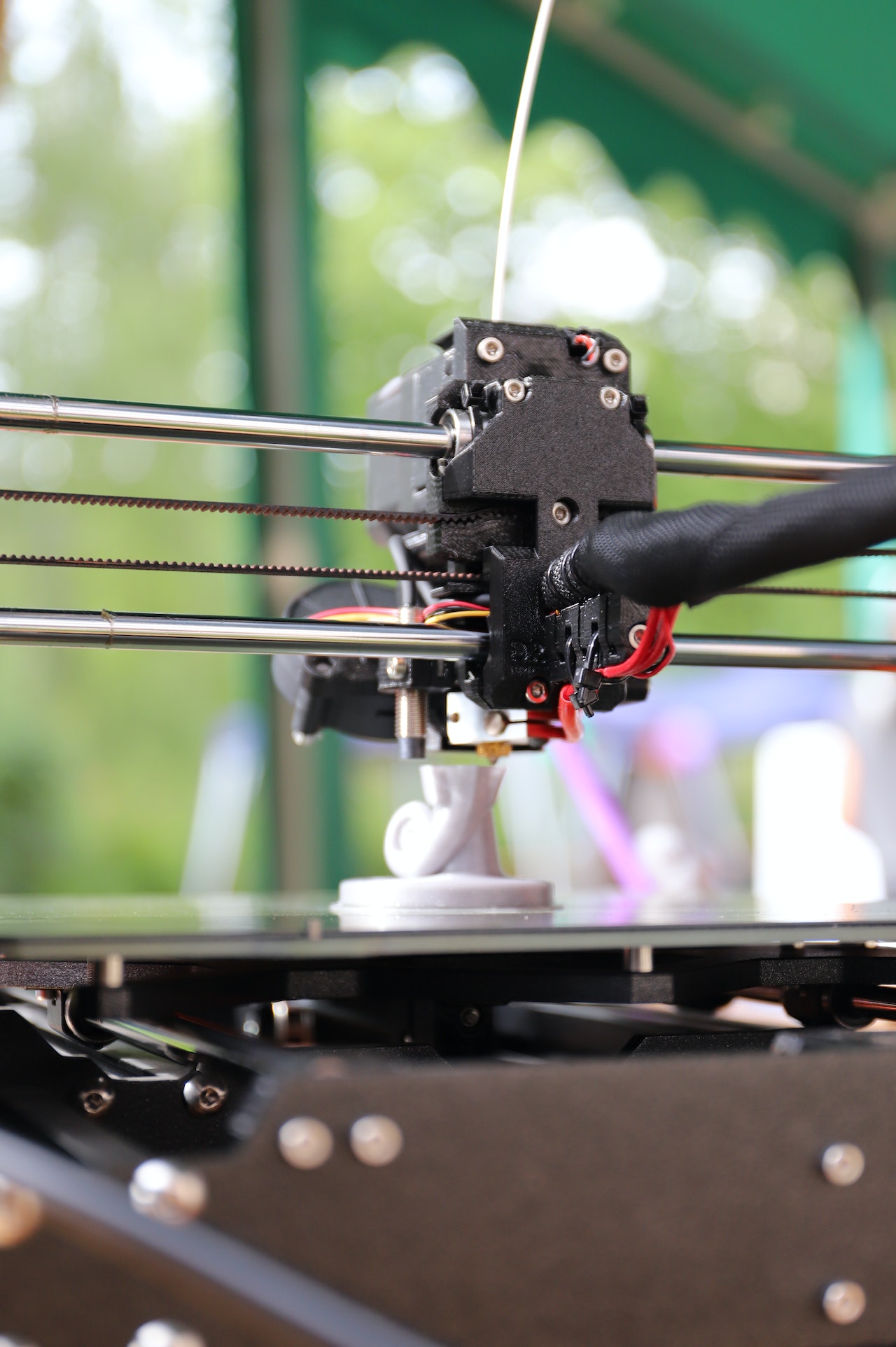

The 21C supercar has taken the automotive world by storm with its exceptional performance, a feat achieved through cutting-edge manufacturing processes. Czinger, in collaboration with its parent company Divergent, leverages 3D printing, additive manufacturing (which involves the use of lasers and metal dust to craft otherwise impossible components), and artificial intelligence (AI) to design components that are both robust and lightweight. The 21C’s groundbreaking construction methods have attracted significant attention from investors eager to join Czinger’s innovative journey.

Czinger’s unique approach to manufacturing extends to its production of bespoke parts for the 21C supercar, which are meticulously designed using AI to fulfill crash and durability requirements while minimizing weight to enhance performance. These designs are then translated into reality through additive manufacturing and 3D printing, creating what Czinger affectionately calls “LEGO blocks.” These individual components are brought together by a sophisticated robotic assembly system, aptly named the “robotic octopus.” This system, quite distinct from traditional assembly lines, employs laser welding and adhesive bonding to meticulously assemble the intricate pieces of the supercar.

“We are a materials company. We’re an additive manufacturing company, and we’re actually an assembly company as well,” emphasized Czinger’s COO, Lukas Czinger, the founder’s son. As he showcased the rear subframe of the 21C, Lukas highlighted the remarkable blend of AI-driven generative design, novel aluminum alloys, 3D printing, and fixture assembly that comprises this critical component. This area alone boasts approximately 450 patents, with the overall system boasting a staggering 650 patents.

Beyond crafting their exceptional supercars, Czinger and Divergent are diversifying their portfolio to cater to external partners. Notably, Czinger has signed agreements to produce precision-made components for esteemed companies such as Aston Martin, Mercedes, and more than 30 aerospace firms, including the latest addition, General Atomics.

During a recent media event held in Lower Manhattan, a C21 supercar on display drew a large and captivated crowd, particularly among astonished and delighted children. Kevin Czinger elucidated the intricate manufacturing process, emphasizing the integral role of AI in generating designs that meet the highest safety standards while optimizing performance.

As excitement builds for the first deliveries of the 21C supercar to its eager customers in Q4 of this year, Czinger and Divergent are preparing for a swift and substantial expansion. Currently operating from facilities near Los Angeles International Airport in Torrance, California, the company plans to establish an additional 30 facilities by the end of the decade. These facilities will serve as hubs for designing, fabricating, and producing custom parts on a larger scale. With over $700 million in capital raised to date, Czinger and Lukas Czinger are well-positioned to fuel their ambitious growth plans.

The road ahead for Czinger promises to be filled with innovation, as the company continues to push the boundaries of automotive manufacturing while supporting partners in their quest for precision and performance. With the 21C supercar finally hitting the streets, the world eagerly awaits the next chapter in the journey of technological advancement and automotive excellence by Czinger.

Source: Yahoo Finance